Wanting to use yarn from my stash is always a challenge. I’ve

wanted to weave a set of fine tea towels using 2/16 cotton for some time and

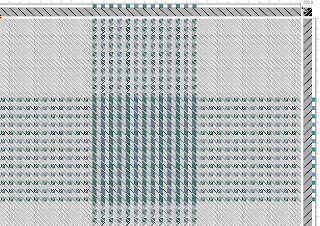

I’ve wanted to try out this colour and weave twill pattern that looks just lovely with the tiny pinwheel stars.

Off I went into my stash cupboard and found that I had some

lovely blue and green cotton in 2/16, but I didn’t have anything that went with

them. What I found was some 24/4 white

cotton which has approximately the same yards per pound.

Then came the realization that the ends per inch needed to

be somewhere between 30-40 threads ~ 30 for loose plain weave, and 40 for lace

weave. Since I was doing twill I decided

on 36 ends per inch. My final thread

count is 868 ends for a 24 inch tea towel and that is more heddles per shaft

than I have on my loom. First order of

business, move heddles from shafts 11 and 12 onto shafts 1 to 8; this is fairly straight forward on the Louet Spring loom, but it sure hurts your fingers after a few shafts! I'm thinking this is my first big mistake.

The plan is to weave 6 tea towels at 36 inch long each, so I

pulled a warp of 242 inches. This is

just shy of 7 yards but still gives me lots of loom waste and take-up. Since I had 2 cones of the white cotton yarn

I decided to pull them at the same time, but to separate them at the cross to

keep them in order. This proved to be my second big mistake, and the reason is torque.

As the thread is pulled up off the cone it creates a spiral and by using

2 cones at the same time, the spiral turned into twist. I pulled the warp in 3 sections over 2 days

because it was a tad tedius. I’m already

having doubts about this project.

This is how it looked as I was trying to pull the warp onto

the loom. This was such a nasty warp to

pull on that it took 2 people 1-1/2 hours to get it through the raddle and

beamed because the torque was immense.

Starting to really dislike this project!

Nothing but snarls and twists as the threads passed through the raddle!

And even more sticking and bridging as they tried to pass through the lease sticks.

I had to stop and strum the warp with the back of my fingers to separate the web, every half turn of the back beam ~ awful!

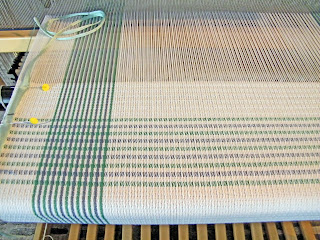

Right now I’m threading the loom and up pops my next

challenge; bear with me while I explain my problem. When I work out the pattern on the computer I

have the tie up on the top right of the screen, when I pull the warp on the

warping board I start at the same place, but start building my warp from the

back left of the loom. So when I start

to thread I’m sitting at the loom and I start threading from right to left and

that is from the left of the screen printout.

Normally this is not a problem, but on this particular colour and weave pattern if you

thread it backward the pattern does this and you lose the star pattern.

There is another very odd foible in this pattern, if you

don’t get the threading and treadling exactly right you get this. Not only do you lose the stars but you lose the rest of the pattern.

Because of the way I put the warp on the back beam I’m

having to thread my heddles from left to the right to make sure it works out. I'm finding it completely counter

intuitive and it’s taking me forever to get anywhere, but I have to admit that it's looking really, really lovely.