Just before the summer break, the Qualicum Weavers Guild has a pot luck lunch and this year they included, a car boot sale (it maybe an annual thing I don’t know, I’ve only been a member since October). We picked up some goodies, how can you resist?!

The first are two monographs. One is Seven Projects in Rosepath by Berta Frey, it is a guided monthly program written for a Weaver’s guild. The second is Handloom Weaves by Harriet Tidball, it is a reference book that defines all the different types of weave structures and gives some basic drafts as examples. Both are absolutely amazing resources.

We got a few of cones of Mohair in pinks and ink blue. This will allow us to use up some cones that we have kicking around that aren’t enough to do anything with. Now we have enough to do some throws or blanket scarves. The Mohair is a little frosty because we put it in the freezer for a week, then took it out for a couple of days and then put it back in the freezer for a week. It is just a preventative measure to make sure that there aren’t any carpet beetles or moths in the cones; these were perfect.

I was gifted a large cone of mystery fibre by one of the guild ladies. It is very fine, probably 2/30 in a creamy white colour. The cone has a lovely silky feel to it. The lady who gave it to me said that the cone was manufactured in Abbotsford, BC and that there was some wool fibre content.

So out comes the book The Key to Weaving by Mary E. Black.

In the back is a section called Burning Tests for Fibers. We did a quick read through the descriptions of the flame, smoke and smell before starting the burn, just to know what to expect.

We did the first burn test using matches and that wasn’t a good idea. The smell of the match overwhelmed the smell of the burning sample. So we changed to a click lighter for the next sample.

The flame was orange yellow, blue/grey smoke, smell was of burnt paper and it ignited easily. There is a black skeleton and no ash. So we think that the sample is cotton.

If the sample was wool the smoke would have smelt like burnt hair and the skeleton would be swollen and irregular in length. So now I have a lovely cone of fine cotton to use and I already have an idea!

Final Garden shot is Gooseneck Loosestrife (Lysmimachia clethroides) and Beardtongue (Penstemon ‘Garnet’), both growing lushly in the back garden!

Showing posts with label Weaving Yarn. Show all posts

Showing posts with label Weaving Yarn. Show all posts

Tuesday, June 28, 2016

Sunday, February 14, 2016

Fibre Binder – An Update

Every January Mum and I pull out the stash to do an updated inventory list. The stash lives in the hallway linen closet and everything (pretty much) lives in a tub. Please note, when all the stash is put away, there is no room in the inn!

Each tub is filled with a single type of fibre. In the below picture is the tub for mercerized cotton of various sizes. Somehow over the year a cone of linen/cotton blend snuck in!

So the tubs get a good tidy up and the cones all get re weight for the Fibre Binder. Mum developed the Fibre Binder in March 2009 and we are still using it! Honestly, it makes it much easier to keep track of what we need to buy to compliment a yarn because it can come along for the shopping trip!

The binder is divided into sections based on fibre and grist. Each cone of fibre is weigh and a small piece snipped off to show colour. Manufacturer, colour name, and anything else we know about the yarn are also added. We try to keep it updated throughout the year but sometimes in the rush to move onto the next project we forget; so doing it right away in the New Year sets the tone for the year!

This year we did a little cull of things that we just aren’t going to use in the foreseeable future. There are cones of wool, cotton, chenille and linen. Everything is being donated to a sale in March with the proceeds going to the charity Grandmothers to Grandmothers. The Stephen Lewis Foundation launched the Grandmothers to Grandmothers Campaign in March 2006, in response to the emerging crisis faced by African grandmothers as they struggled to care for millions of children orphaned by AIDS.

Final Photo is the Comox Glacier. It dominates the landscape in our area. It is truly huge and there is something majestic about it.

Each tub is filled with a single type of fibre. In the below picture is the tub for mercerized cotton of various sizes. Somehow over the year a cone of linen/cotton blend snuck in!

So the tubs get a good tidy up and the cones all get re weight for the Fibre Binder. Mum developed the Fibre Binder in March 2009 and we are still using it! Honestly, it makes it much easier to keep track of what we need to buy to compliment a yarn because it can come along for the shopping trip!

The binder is divided into sections based on fibre and grist. Each cone of fibre is weigh and a small piece snipped off to show colour. Manufacturer, colour name, and anything else we know about the yarn are also added. We try to keep it updated throughout the year but sometimes in the rush to move onto the next project we forget; so doing it right away in the New Year sets the tone for the year!

This year we did a little cull of things that we just aren’t going to use in the foreseeable future. There are cones of wool, cotton, chenille and linen. Everything is being donated to a sale in March with the proceeds going to the charity Grandmothers to Grandmothers. The Stephen Lewis Foundation launched the Grandmothers to Grandmothers Campaign in March 2006, in response to the emerging crisis faced by African grandmothers as they struggled to care for millions of children orphaned by AIDS.

Final Photo is the Comox Glacier. It dominates the landscape in our area. It is truly huge and there is something majestic about it.

Tuesday, June 17, 2014

Tartan Yardage Completed ~ Lynch Tartan

My tartan yardage has been off the loom for awhile now and I just remembered that I haven’t shown you the finished product.

It made a lovely looking log of tartan as I pulled it off the loom.

I ran out of the Ancient Blue wool weft when I was well into the 8 yards; I substituted grey/olive marled wool in the same grist for the weft that I luckily had on hand. You can definitely see the difference between the two wefts; the true tartan wool is much smoother and has more lustre than the run of the mill wool weft. However, the grey/olive weft shows the green up much more than the Ancient Blue. This photo is before washing to full the cloth.

The definition of Ancient colours is that they are distinct from modern colours by being less saturated in tone and lighter in shade. The term ‘modern’ refers to the aniline dyes introduced around 1860 which produce darker greens and blues and richer reds and yellows. The term ‘ancient’ should no be confused with the age of the design.

I thought I’d give you some weaving statistics for this yardage. I sett the warp at 28 ends per inch, 2 per dent in a 14 dent reed.

The On loom Width was 32 inches ~ The On loom length was 8 yards.

The Off loom width was 30 inches for the Lynch Tartan ~ The Off loom lengths was 5 yards 29 inches.

The Off loom width was 30 inches for the Plaid piece ~ The Off loom length was 1 yard 12 inches.

The Loom waste in the warp was 15 inches at the end and 4 inches at the tie on for a total of 19 inches.

I washed the yardage in my front loader machine on a cycle that took 25 minutes. I want the yardage to be well fulled and this was the least time my machine could do, and frankly I just wasn't prepared to do it by hand. I used the tiniest amount of organic laundry soap in the wash. Ahhh, I’m wishing for the days when I could open the top of the machine and pull my weaving out when I thought it looked right, sadly those days are long gone and I have to wait for the full cycle!

I folded the yardage a few times so that it fit on the drying rack and put it outside in the shade to dry.

The finished width was 29 inches for the Lynch Tartan ~ The finished length was 5 yards 24 inches long.

The finished width 27-2/4 inches for the Plaid piece ~ The finished length was 1 yard 10 inches long.

The secondary weft caused more shrinkage than the Lochcarron Wool weft; but overall there was very little shrinkage ~ not even 1%!

This is the tartan before it was pressed.

You can see a huge difference in the fabric after just one pass through the steam press. This yardage is amazingly supple and light and has a fabulous sheen, really lovely.

My plan for much of this yardage is to frame a piece for each of the members of the family and maybe get a garment for myself.

The Europeans have a phrase for one slow truck trying to pass another slow truck on the highway ~ an elephant race ~ well, this yardage and Ngaires shawls were our elephant race! Thankfully, both are off the looms and we are ready to weave again!

It made a lovely looking log of tartan as I pulled it off the loom.

I ran out of the Ancient Blue wool weft when I was well into the 8 yards; I substituted grey/olive marled wool in the same grist for the weft that I luckily had on hand. You can definitely see the difference between the two wefts; the true tartan wool is much smoother and has more lustre than the run of the mill wool weft. However, the grey/olive weft shows the green up much more than the Ancient Blue. This photo is before washing to full the cloth.

The definition of Ancient colours is that they are distinct from modern colours by being less saturated in tone and lighter in shade. The term ‘modern’ refers to the aniline dyes introduced around 1860 which produce darker greens and blues and richer reds and yellows. The term ‘ancient’ should no be confused with the age of the design.

The On loom Width was 32 inches ~ The On loom length was 8 yards.

The Off loom width was 30 inches for the Lynch Tartan ~ The Off loom lengths was 5 yards 29 inches.

The Off loom width was 30 inches for the Plaid piece ~ The Off loom length was 1 yard 12 inches.

The Loom waste in the warp was 15 inches at the end and 4 inches at the tie on for a total of 19 inches.

I washed the yardage in my front loader machine on a cycle that took 25 minutes. I want the yardage to be well fulled and this was the least time my machine could do, and frankly I just wasn't prepared to do it by hand. I used the tiniest amount of organic laundry soap in the wash. Ahhh, I’m wishing for the days when I could open the top of the machine and pull my weaving out when I thought it looked right, sadly those days are long gone and I have to wait for the full cycle!

I folded the yardage a few times so that it fit on the drying rack and put it outside in the shade to dry.

The finished width was 29 inches for the Lynch Tartan ~ The finished length was 5 yards 24 inches long.

The finished width 27-2/4 inches for the Plaid piece ~ The finished length was 1 yard 10 inches long.

The secondary weft caused more shrinkage than the Lochcarron Wool weft; but overall there was very little shrinkage ~ not even 1%!

This is the tartan before it was pressed.

My plan for much of this yardage is to frame a piece for each of the members of the family and maybe get a garment for myself.

The Europeans have a phrase for one slow truck trying to pass another slow truck on the highway ~ an elephant race ~ well, this yardage and Ngaires shawls were our elephant race! Thankfully, both are off the looms and we are ready to weave again!

Labels:

Finished Project,

Sewing,

Steam Pressing,

Weaving Yarn

Friday, May 9, 2014

Fiber Fair

Today I added a

new page to my blog ~ a for sale page! I

have no idea how I’ve managed to acquire so much stuff! Please have a quick

look because there are some real bargains to

be had.

On a much more

interesting note last Saturday we went to the Fiber Fair in Campbell River

I was especially

happy to find a booth for The Weavers Atelier. They are so new to Vancouver

Island that they haven’t opened yet, but lucky for me they brought

some weaving yarn with them. Linda is also the Guild of Canadian Weavers

current president and it’s great to have such a strong West Coast presence in

the guild.

I was so happy to

get my hands on 16 ounces of 2/20 silk because dyeing season is almost here and I love to paint the silk, although I still haven't finished weaving last years batch of silk warps.

I also found some Brassards 2/8 unmercerized cotton in a stunning peacock blue/green and

the navy to cross it with…..I’m seeing tea towels on the horizon.

The weather here

continues to be cool and rainy, but that’s just fine by me as it keeps me at

the loom.

I am about 2

yards into the Lynch family tartan and so far, so good although I’ve had every

problems know to a weaver ~ mis-selying, mis-threading; basically if I could

make a mistake I did! But, doesn't it look lovely!

Labels:

Silk Painting,

Tartan,

Weave Structure,

Weaving Yarn

Sunday, February 9, 2014

12 Shaft Fancy Twill - Second Scarf

I’m almost

finished the second scarf that I plan to gift to my hostesses while we visit New Zealand

I’ve tried a

different hem treatment on these scarves.

Usually I hemstitch with the weft that I weave the body of the scarves

with. But, I must admit that sometimes

I’m not happy with the overall look of the stitches, even though I usually pick

up very small increments. This time I’ve

use the same colour as the warp to start.

I wove 2 picks in black and then hemstitched over two dents ~ 4

threads. Then I started the pattern weft

colour, on the first pick I carried the black thread also. Pretty nice I think!The scarf has a slightly different look on the underside where the black warp is more predominant.

This is the first time I’ve woven with soy silk and I must say it’s behaving very well so far. This soy silk was hand dyed and has a very slight colour shift which adds some additional colour interest.

I have noticed that the soy silk is not as lustrous as tencel, but I’m hoping that pressing will bring up more sheen.

My husband and I have taken the big plunge and have decided to travel for a full month to

I also found a great

video Packing Light and I did a trial pack using this method. Amazingly, I was able to get 2 pairs of

Capri’s, a pair of trousers, 9 tops, a bathing suit, 2 pair of sandals, a

jacket, undies and my travel appliances into a 21 inch wheeled carry-on. The whole shebang ended up weighing 12.7

pounds! Admittedly I’m a small gal, but

I tried it out for my husband who’s over 6 feet and he had space to spare! I still have some trepidation but I'm feeling really good about it so far!

Sunday, January 26, 2014

12 Shaft Fancy Twill - Four Scarves

This is the first warp

after Lily Louet's new year tune up, a 2/10 black tencel warp. I purchased this yarn from Yarns Plus before

they (alas!) closed their doors. Since the cone

was getting low, I had a look online for replacement yarn and couldn’t find

anyone who carries 2/10 black tencel! Do

any of you know of a supplier that you will share with me?

The warp I put on

the loom is 9.5 yards long for four scarves, each scarf has been allocated 83

inches which will be 68 loom woven inches and 7 inch fringe allowances. The first scarf has a 10 inch fringe to allow

tie on to the front beam and the last scarf has a final fringe of 16 inches to

allow for loom waste included.

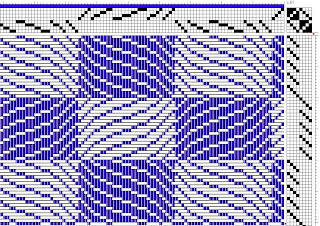

The pattern I’m weaving is 12 shaft fancy twill that I developed based on a combination two patterns. The first pattern was shared by my friend Susan and she showed it on this post. The second inspirational pattern was found in Handwoven’s Design Collection #19 called ‘Peacock Shawl’.

The pattern I’m weaving is 12 shaft fancy twill that I developed based on a combination two patterns. The first pattern was shared by my friend Susan and she showed it on this post. The second inspirational pattern was found in Handwoven’s Design Collection #19 called ‘Peacock Shawl’.

I’m weaving the

scarves so that I can take them with me on my New Zealand Ardmore

Teachers College

I’ve already

finished the first scarf and I’ve started the second scarf in 2/10 soy silk in

a lovely hand dyed bronze.

As you probably

know I live on Vancouver Island and frankly a

moist environment is an understatement.

Today it’s dense fog and 100% humidity!

Needless to say wearing wool in the winter is a must for me, but I hate

the tendency for wool to pill and make you look unkept.

I bought this

great gadget by Conair called a Fabric Shaver and I can’t say enough great

things about it! There is a guard that allows you to choose how close you come to the fabric ~ security blanket for me!

Here it is with

one sleeve done, much, much better!

This is just the first part of the pile of pills I removed ~ amazing ~ I'm all back to smooth and warm.

Labels:

Handwoven Magazine,

Twill,

Weave Structure,

Weaving Yarn

Saturday, July 27, 2013

Stripes and Squares Scarf

On this pair of scarves I am weaving specifically to sell on Etsy, so having a variety of scarf styles is very important to the look of the shop. Periodically I have a look at the overall appearance of the pages and try and spot any colour or style voids. Right now I seem to have a need for black and for stripes.

With that in mind I pulled a 2/8 tencel warp that has stripes in the following sequence 8 black, 2 slate grey, 2 blueberry, 4 silver, 2 white, 3 lemon drop and then the reverse. When I move into the next stripe I don’t double the number of black ends. The scarf has 5 stripes in total for a total of 163 ends which ends up as 6.8 inches wide.

I think it looks really neat over the back beam!

The weave structure is modified twill with some of the ends duplicated in the pattern.

Next to decide on the weft colour, after trying some of my other options; slate, black, navy and white….I chose this lovely grayed lavender. My goal was to make the first scarf fairly light coloured and to not hide any of the colours in the warp.

I have woven this pattern before with a different treadling and colour pallet. I found that if I wove long runs treadled 1-2-3-4 it produced stunning hills and valleys that gave an optical illusion but came with a price. Even after extensive wet finishing the weft threads tended to slip on the warp threads due to the smoothness of the tencel!

Needless to say, the scarf couldn’t be sold and I’m thankful for that because it is my very favourite to wear, warts and all it has a wonderful drape.

What I did discover is that if I treadled it in short runs the warp/weft was very stable, so here is a close up!

With that in mind I pulled a 2/8 tencel warp that has stripes in the following sequence 8 black, 2 slate grey, 2 blueberry, 4 silver, 2 white, 3 lemon drop and then the reverse. When I move into the next stripe I don’t double the number of black ends. The scarf has 5 stripes in total for a total of 163 ends which ends up as 6.8 inches wide.

I think it looks really neat over the back beam!

The weave structure is modified twill with some of the ends duplicated in the pattern.

Next to decide on the weft colour, after trying some of my other options; slate, black, navy and white….I chose this lovely grayed lavender. My goal was to make the first scarf fairly light coloured and to not hide any of the colours in the warp.

I have woven this pattern before with a different treadling and colour pallet. I found that if I wove long runs treadled 1-2-3-4 it produced stunning hills and valleys that gave an optical illusion but came with a price. Even after extensive wet finishing the weft threads tended to slip on the warp threads due to the smoothness of the tencel!

Needless to say, the scarf couldn’t be sold and I’m thankful for that because it is my very favourite to wear, warts and all it has a wonderful drape.

What I did discover is that if I treadled it in short runs the warp/weft was very stable, so here is a close up!

Labels:

Etsy,

PCW Fiberworks,

Weaving Draft,

Weaving for Sale,

Weaving Yarn

Thursday, March 7, 2013

Sugarcane Fiber

It seems that lately every project that I put on the loom has a weird story…and my newest project is no exception. I’m still on my stash busting frenzy and I’m determined to make use of everything!

I bought two skeins of this amazing Sugarcane fiber yarn made in Chile while I was visiting my friend Susan in Duncan B.C. This yarn is made up of 6 strands of 2 ply sugarcane fiber that has been hand dyed and it is uber soft.

The beautiful tonal blue, pink and lilac just reached out to me and I thought I’d make a scarf with it. I had just had my Leno scarves published in Handwoven magazine May/June 2011 and I though this yarn would look great woven with the same Leno technique.

I started weaving and it was immediately apparent that the thickness and springiness of the yarn made the Leno technique on the edges of each square impossible. So, I cut if off the loom…this left me with 20 ends 6 yards long and 40 ends 3 yards long and my weft on a stick shuttle. I had no idea how I was going to use it, but someday…..

Well today is the day and I’ve just warped the loom for a spring scarf.

I pulled groups of 28 ends of 2/8 tencel in lilac in individual bouts and slipped each one over the back rod. Each block was bracketed with 7 ends of the sugarcane. The 20 ends of the sugarcane that were 6 yards long could be folded over the back rods, but the ends that were only 3 yards long had to be individually tied on….what a pain. But I think it was worth it!

I’ve just woven a few inches and I am really thrilled with the way the sugarcane adds both texture and amazing colour to the scarf. The tencel stripes are in alternating twill and the 7 ends of sugarcane fiber are in point twill. A very simple pattern but stunning don’t you think?

I bought two skeins of this amazing Sugarcane fiber yarn made in Chile while I was visiting my friend Susan in Duncan B.C. This yarn is made up of 6 strands of 2 ply sugarcane fiber that has been hand dyed and it is uber soft.

The beautiful tonal blue, pink and lilac just reached out to me and I thought I’d make a scarf with it. I had just had my Leno scarves published in Handwoven magazine May/June 2011 and I though this yarn would look great woven with the same Leno technique.

I started weaving and it was immediately apparent that the thickness and springiness of the yarn made the Leno technique on the edges of each square impossible. So, I cut if off the loom…this left me with 20 ends 6 yards long and 40 ends 3 yards long and my weft on a stick shuttle. I had no idea how I was going to use it, but someday…..

Well today is the day and I’ve just warped the loom for a spring scarf.

I pulled groups of 28 ends of 2/8 tencel in lilac in individual bouts and slipped each one over the back rod. Each block was bracketed with 7 ends of the sugarcane. The 20 ends of the sugarcane that were 6 yards long could be folded over the back rods, but the ends that were only 3 yards long had to be individually tied on….what a pain. But I think it was worth it!

I’ve just woven a few inches and I am really thrilled with the way the sugarcane adds both texture and amazing colour to the scarf. The tencel stripes are in alternating twill and the 7 ends of sugarcane fiber are in point twill. A very simple pattern but stunning don’t you think?

Labels:

Handwoven Magazine,

Published,

Weave Structure,

Weaving Yarn

Saturday, October 6, 2012

Project Based on Handspun Merino

My plan was to weave a shawl using my handspun and some of the new 50/50 Silk Wool blend I’d just purchased. I also wanted to have two unique sides to the shawl and to have surface interest. Here's my draft.

I didn’t want to use my favourite Schacht end feed shuttle because it just doesn’t hold all that much of this fairly uneven yarn, so I used this 15 inch Little Man Howell shuttle which holds an amazing amount of yarn. What you can get on this shuttle is astonishing!

I didn’t have a temple that was wide enough (well, actually I do have one, but it’s a Leclerc rug stretcher and it’s really heavy and so not a good choice for this lightweight fabric), so I made this simple home made version using paper clips, string and weights. It hangs over the sides of the loom and really, really works!

I filled film canisters with pennies for the weights ~ this is a great solution and I found the idea here.

Side number 1 of my pattern consists of 2 inch stripes of handspun and commercial yarn alternating and you can already see how it’s already starting to pleat! I sett the yarn at 12 epi and hopefully this is not too close a sett. I didn’t want a sleazy fabric and I know that twill needs more epi than plain weave, so I’m still at the ‘fingers crossed’ stage and hope it works out. As you can see from the streaking, my handspun was a tad unevely blended.....ahhh but that's the nature of the beast!

Side number 2 was really hard to photograph, but you can just make out the pleats and the all over handspun with each 2 inch stripe.

I'm almost finished and can't wait to see how it washes and pleats.

Labels:

Handspun,

Weaving Draft,

Weaving Tools,

Weaving Yarn

Subscribe to:

Posts (Atom)

.JPG)