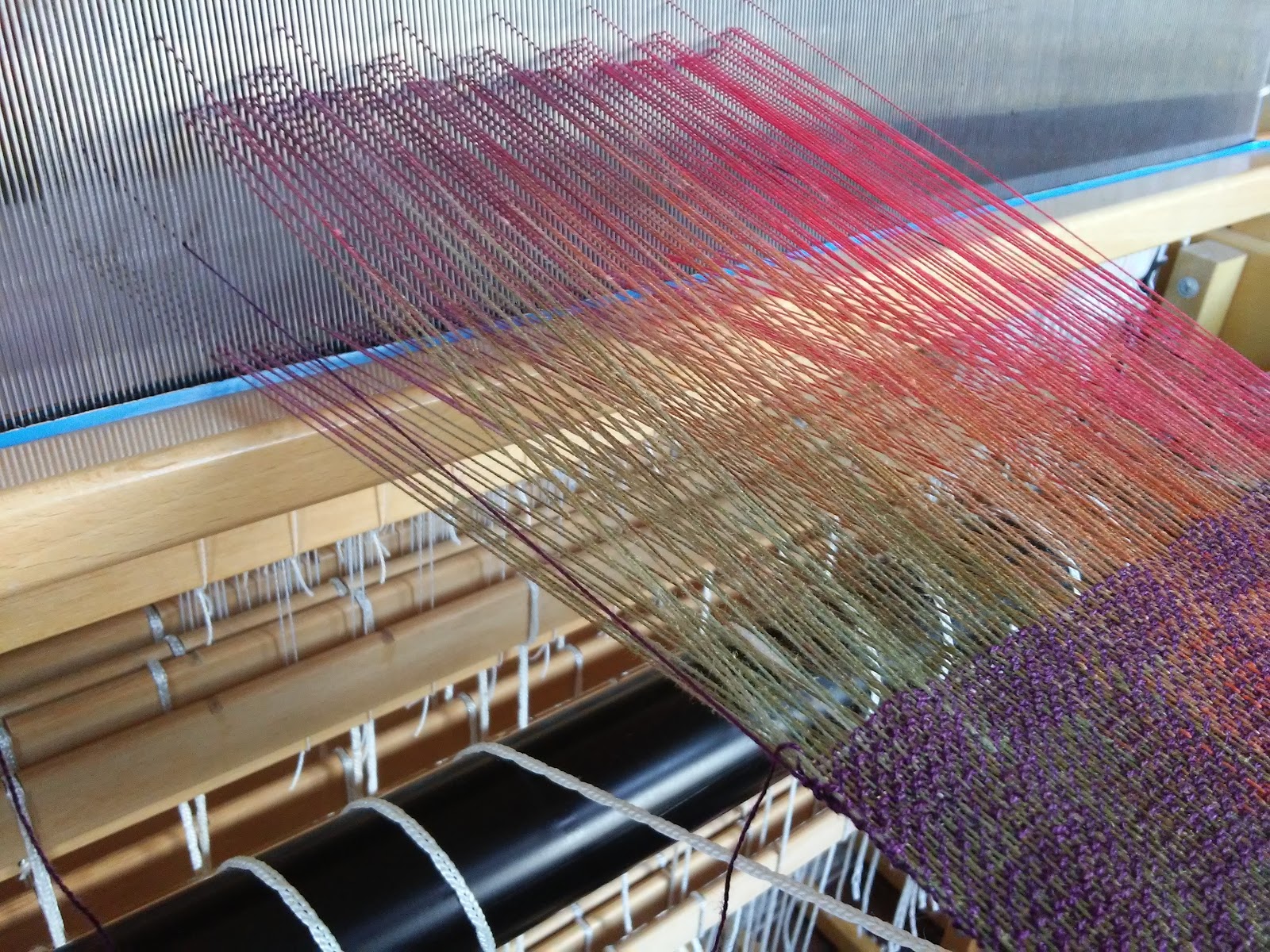

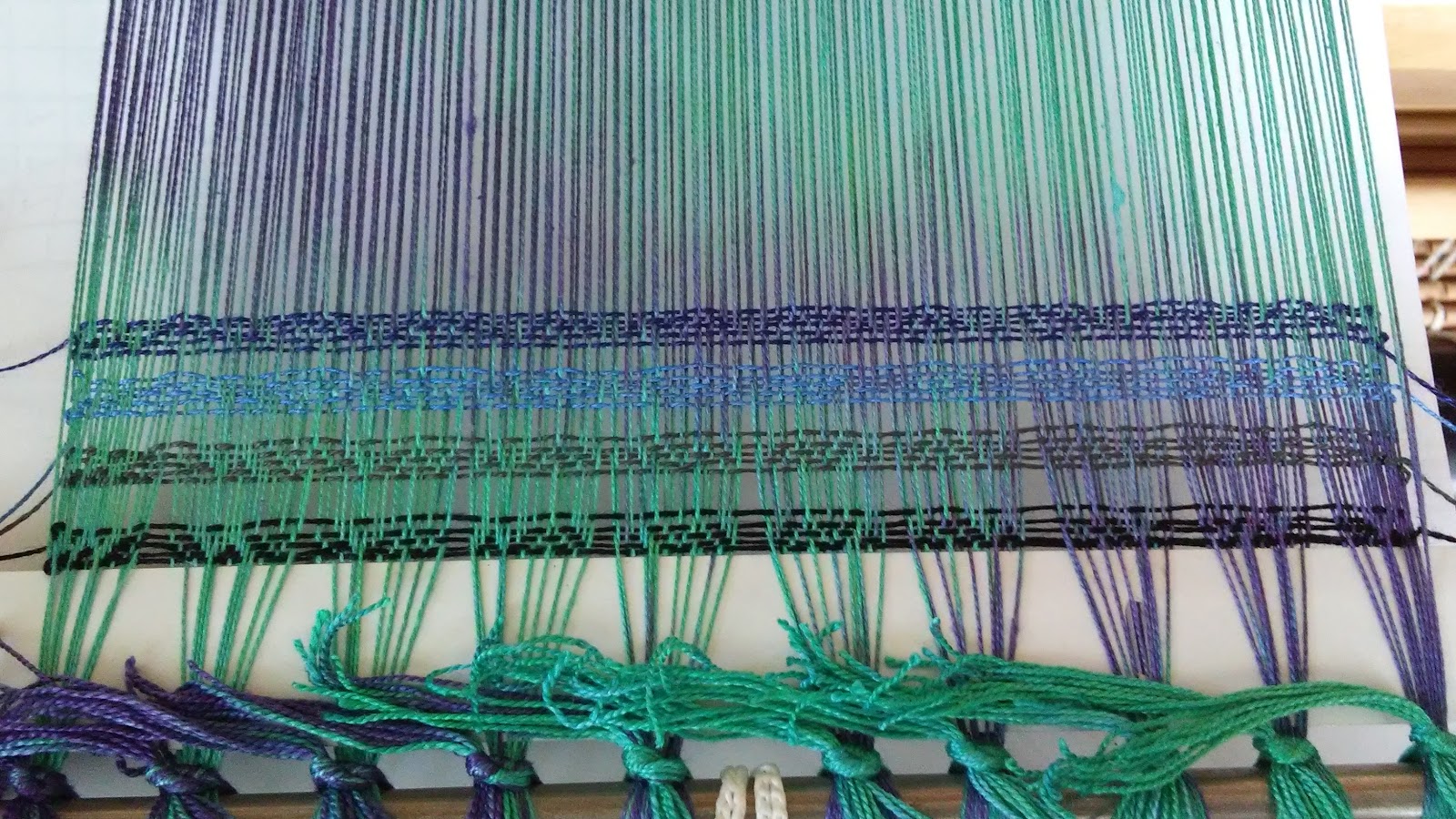

Mom and I have switched back to our original looms but we both decided to reuse the weaving patterns that are on the looms, in my case it is a lovely 8 shaft fancy twill. I put on another hand painted silk warp, this one is 2/22 and is a lovely fresh green with a sinuous purple curves.

For the weft I was sure that a blue would be perfect, but I tried royal blue, navy and light blue 2/8 Tencel. The darker blues matched the purple and would have hidden the pattern and the light blue over powered everything.Next I tried Tencel in straw, taupe and birch, a silvery green. They are brave choices but weren’t the right one.

The last round I tried black, charcoal, a different blue and a different navy. The clear winner here is the black, it makes the green and purple pop.

The pattern is a beautiful fancy twill from Strickler with large diamond and cross motifs.

I quite like the juxtaposition of the formality of the pattern with the organic movement of the colours on the warp, it makes for an interesting dichotomy. I think that the finished scarf will be fantastic.

Final Garden Photo is Hydrangea paniculata 'Vanille Fraise' the shrub is over 6 feet tall and the heads are at least 1 foot in length. The flowers start as white in the summer then as the nights get cooler they start to pinken going all the way to dark pink. The charming blue violet flowers is hardy Geranium 'Rozanne' it spreads 2-3 feet and flowers until the frost. The small pink flowers are fall blooming Japanese Anemone called 'Fall in Love Sweetly', and they truly live up to their name!

.JPG)